UK Specialists in H&S Approved Floor Pendulum Testing for Businesses

and CPR 35 / COPFS Expert Witness Services for Slip Injury Lawyers

FloorSlip

You are here >

Comments from Our Customers … “FloorSlip is a great source for Floor Safety expertise and Floor Pendulum Testing” … “The CPR35/COPFS Expert Witness reports for Slip Injury Lawyers are clear, unequivocal, affordable and assist in winning Slip Injury Claims”

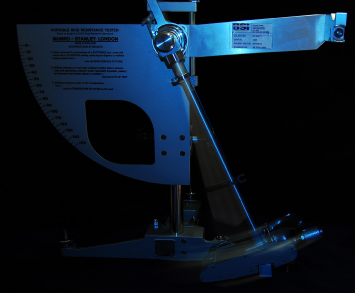

Conducting The Pendulum Test

The Floor Pendulum Test is the only floor testing recommended by the UK HSE as suitable to provide consistent, repeatable, dependable results in the case of slip injury claims and for floor safety for businesses. FloorSlip are often asked, particularly by Health and Safety Managers, to describe how we do the Pendulum Test.

Few people have seen pendulum testing conducted and particularly up to 2008 where the law changed (H&S Act 2008) to protect customers, employees and people in care

The HSE / UK Government insist that floor risk assessment is conducted as part of your duty of care and breaches of Health & safety can be punishable by a year in prison and a heavy fine

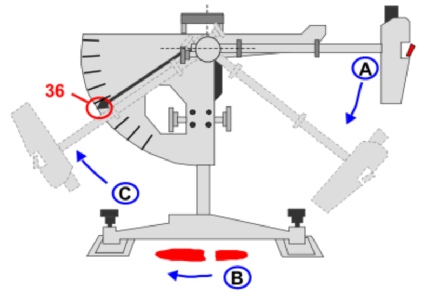

How the Pendulum Floor Test works

The pendulum test equipment uses a rubber slider on the end of a heavy swinging arm. The Pendulum Test arm is raised to a set elevated and accurately measured position (A) and then released. The heavy arm then swings through an arc, the rubber slider making contact with the floor at (B). There is a spring loaded device holding the rubber ‘slider’ on the end of the swinging arm allowing the arm to ‘give’ as it makes contact with the floor and the arm swings through its arc across the floor. The distance the arm travels determines how slippery the floor is (C). The further the arm travels, the less resistance there is and the more slippery the floor.

The Pendulum Test Rubber Sliders used

The ‘sliders’ used typically have two distinctly different hardness’s and must be prepared by levelling and roughening of the rubber surface to a required specifications as determined by the UKSRG Guidelines and BS7976-

Rubber Slider ‘4S’ or ‘96’ Pendulum Test Slider for pedestrian walkways

4S = Standard Shoe Sole Simulating and has an International Rubber Hardness Degree (IRHD*) value of 96 and is used to replicate everyday use with shod feet

Rubber Slider ‘TRL’ or ‘55’ Pendulum Testing Slider is used for road skid tests, rough and profiled floors and wet floor areas such as swimming pools and changing rooms

TRL = Transport Road Laboratories. The rubber hardness (IRHD*) is softer at 55 for this purpose to allow the slider to pass across the floor surface without causing ‘judder’, which can cause results to deviate from true.

*International Rubber Hardness Degree

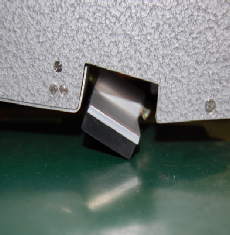

LH Image -

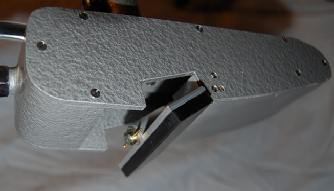

RH Image -

Pendulum Test History

The Pendulum Test was originally developed by a man called ‘Sigler’ and was adapted for use in the UK by the Transport Road Laboratories – hence the acronym ‘TRL’ -

Rubber Sliders, Floor Pendulum Test Equipment and Training Courses are all available through FloorSlip as well as on Site Pendulum Testing and off-site Floor Sample Testing

The ‘On site’ Pendulum Test

Calibrating the Pendulum Tester on the Floor

The Pendulum is set up on the floor ‘spot’ (Or Slip Locus) to be tested by levelling the device using its own inbuilt spirit levels. The swing arm of the pendulum is then lowered to the floor and the height adjusted using a floor surface gauge to determine the replicated ‘footprint’. The ambient temperature is measured and recorded and the device is now ready for floor testing

Carrying out the Floor Test (Or skid test*) – Dry Floor

The floor is wiped clean of debris and dust and is then tested ‘as is’ -

The arm of the Pendulum Test Equipment is swung 3 times to allow the rubber slider to ‘settle’ and then 5 actual test swings are carried out – all 8 swings are recorded and the average of the last 5 determines the Floor Slip Resistance Value (Or Pendulum Test Value)

Repeating the Dry Floor Pendulum Test (Or skid test*) in additional planes

This Pendulum testing procedure of levelling, checking the ‘footprint’ and the 8 swings is then repeated another 2 or 3 times. The UKSRG recommends 3 times at 0, 45 and 90 degrees in the same spot. FloorSlip sometimes do one additional the test in one additional plane where the floor has ‘grain’, for example a wooden floor, and we test along both directions of the grain; the results can be surprisingly different.

Carrying out the Floor Test (Or skid test*) – Dry Floor – Different Locations

The Pendulum Tester then moves the Pendulum Testing Equipment and repeats all aspects again in a different position on the floor; typically we will test at least 3 ‘spots’ –

The first floor spot test in a high footfall area to determine the worse floor slip condition

The second floor spot test close to a wall or where the floor rarely is walked on to determine the typical state of the floor as it might have been when laid from new

The third floor spot test in an area which might experience average footfall.

The Floor Slip Injury Locus is also tested This is necessary where a floor test occurs because of a slip injury claim

Carrying out the Floor Testing (Or skid test*) – Wet Floor

The dry floor is sprayed with tap (potable) water and the whole floor testing regime as described above begins again. The floor is sprayed every time for every pendulum testing swing to replicate the worse condition – example, heavy rain or a floor recently cleaned and still wet.

Contaminated Floor Test (Or skid test*) - Supplementary Test 1 – Dry Floor

If your floors are subject to regular spills or contamination such as oil, blood, urine, sawdust or talcum powder then an additional series of pendulum test swings will be conducted; the dry floor sprayed with a contaminant relevant to the work environment. And for a road skid test, the contaminate might be diesel or vehicle oil.

Contaminated Floor Test - Supplementary Test 1 – Wet Floor

There may be circumstances where a contaminant and a wet floor are in combination – this will also be tested for where required.

How Long does Floor Testing Take?

We expect to take a minimum of 2-

* The test procedure described here is for floors but the same principal is used on roads for a skid test

Please Contact or Call FloorSlip if you have any other questions or you wish to book a Pendulum Test

The Pendulum Test Arm swinging through its arc

Keywords - Pendulum Floor Slip Testing Method to BS7976-1,-2,-3

Services supplied across the UK from Lands End to Dover and Southampton to John O-Groats Contact Northern Regional Office - 07774 323267 - Contact Southern Regional Office 07506 559952. Contact by Phone or E:mail FloorSlip for more info

FloorSlip Limited, Reg No: 07757686 -